Taurus Engineering was successful in engineering a solution to ultrasonically weld a PTFE membrane to PVC demonstrates our expertise in material science, medical device design, and manufacturing processes. The compression stand is a testament to our commitment to developing innovative solutions that contribute to the advancement of medical technology and patient care. This specific assembly requires complying with 21 CFR Part 210 and 21 CFR Part 211. Current Good Manufacturing Practice for Finished Pharmaceuticals.

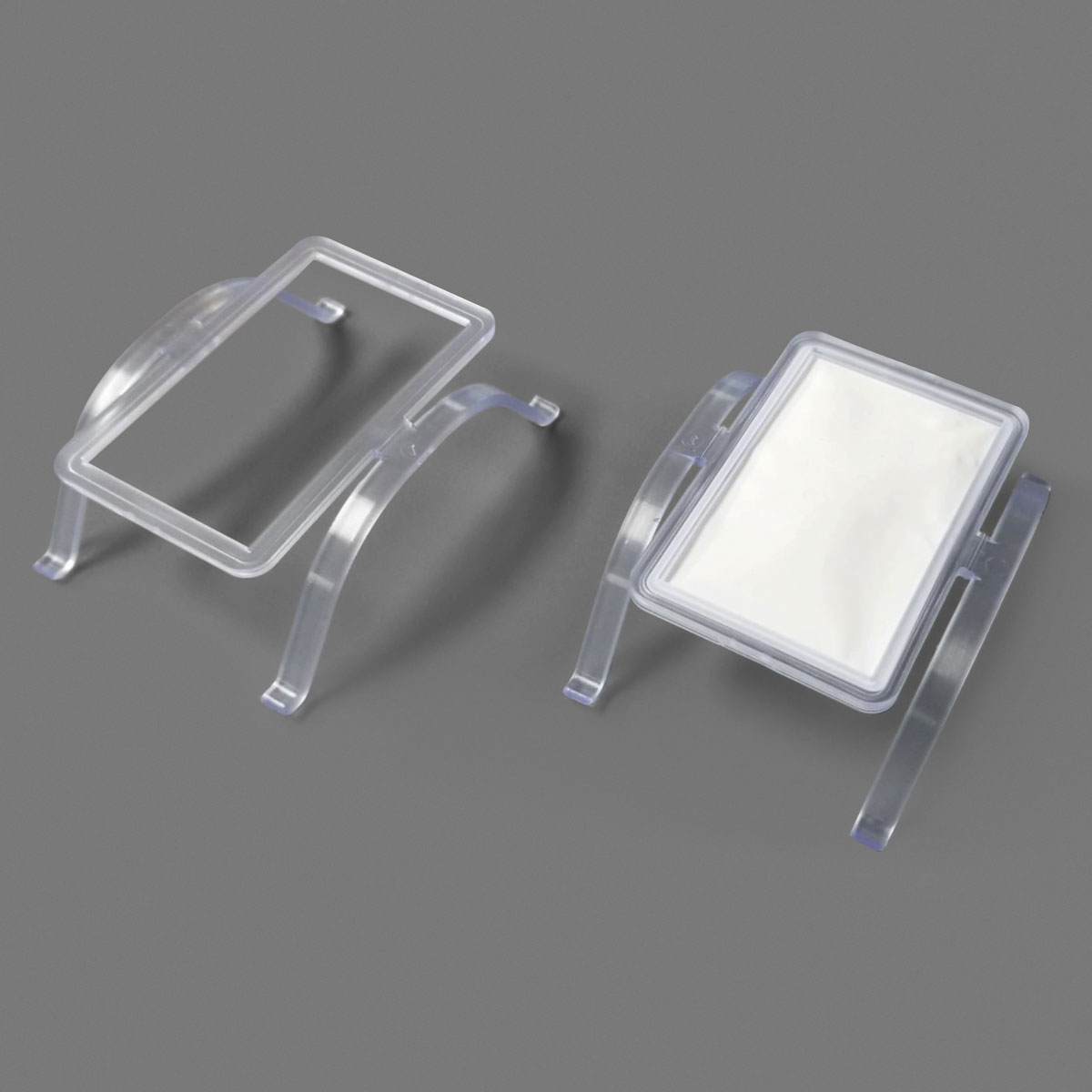

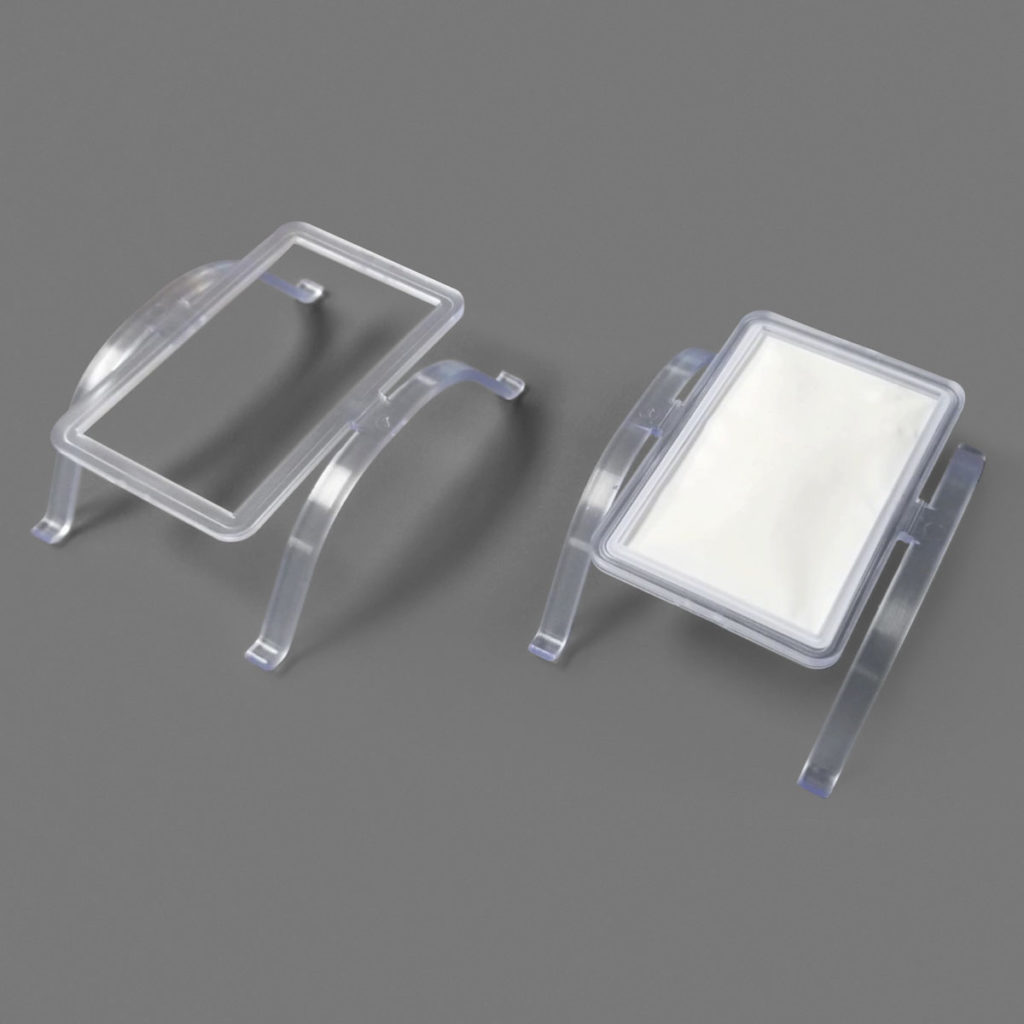

- Filtration Compression Stand: The product developed by Taurus Engineering is a blood filtration compression stand. This stand is designed to hold and compress components made of flexible PVC material and PTFE membrane during the ultrasonic welding process.

- PTFE Membrane to PVC Welding: Ultrasonic welding is a specialized joining process that utilizes high-frequency vibrations to create strong bonds between two materials without the need for additional adhesives or fasteners. In this case, Taurus Engineering has successfully engineered a solution to weld PTFE membrane to PVC using ultrasonic welding technology.

- Filtration Application: The welding of PTFE membrane to PVC is crucial for blood filtration applications. PTFE is known for its non-stick and chemical-resistant properties, making it an excellent choice for filtration applications, particularly in medical settings.

- Disposable Product: The compression stand (tooling) designed by Taurus Engineering is a disposable product. This means it is intended for single use only, eliminating the need for cleaning or sterilization between uses. Disposable medical products are essential for maintaining hygiene and preventing cross-contamination in medical procedures.

- Significance of the Engineering Solution: The successful welding of PTFE membrane to PVC using ultrasonic technology offers several advantages. It ensures a reliable and secure bond between the two materials, which is essential for maintaining the integrity of the blood filtration system during use. Additionally, the use of ultrasonic welding allows for a more efficient and automated manufacturing process, increasing production speed and consistency.

- Industry Impact: Taurus Engineering’s innovation in ultrasonic welding for these applications has a positive impact in the medical industry. Reliable and effective blood filtration is critical for various medical procedures, and the development of a disposable compression stand enhances safety and convenience for healthcare providers and patients alike.