Design For Manufacturability (DFM)

Early Collaboration for Smarter Design

At Taurus Engineering, we believe the best products start with smart design. That’s why we engage early with your engineering team to ensure your parts are optimized for manufacturability. Our goal: reduce revisions, streamline development, and deliver high-quality tooling on time and within budget.

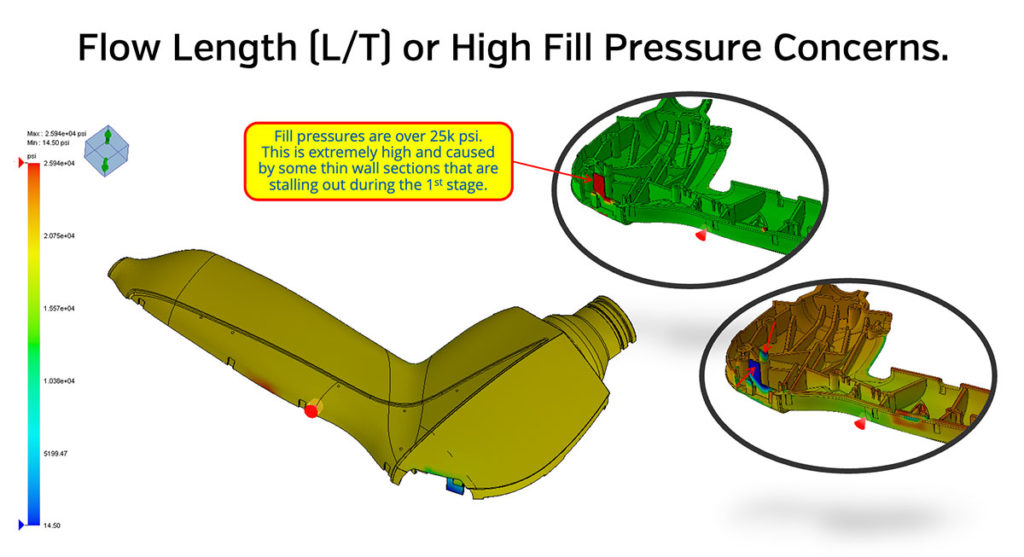

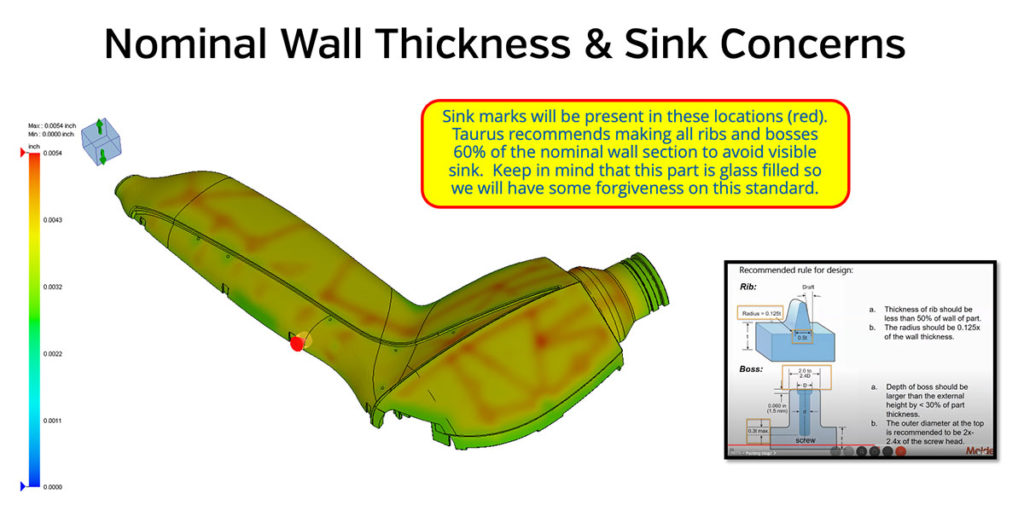

Comprehensive DFM Reporting

We provide a detailed Design for Manufacturability (DFM) report for every part we quote. This report highlights potential challenges early—before steel is cut—setting your project up for long-term success.

Key areas we evaluate include:

- Resin selection and shrinkage behavior

- Parting line location and draft angle analysis

- Fill pattern and mold flow analysis

- Wall thickness, rib design, and thin section review

- Gating strategy

- Location

- Quantity

- Size

- Weld line prediction

- Surface finish and polishing recommendations

- Engraving placement and manufacturability

Design Smarter. Build Faster.

Whether you’re launching a new product or improving an existing one, Taurus Engineering’s DFM process helps you get to market with fewer surprises and greater confidence.