Assembly and Post Molding

Taurus Engineering offers more than just plastic injection molded parts. We provide value-added services through expertise in secondary operations, assembly, and packaging.

We specialize in both manual and automated assembly, including sub-assemblies and full device assemblies, tailored to your specific needs. Our services extend to custom labeling and packaging to meet Just-In-Time (JIT) and Kanban distribution requirements.

Our value-added services include:

- Sub-Assemblies to Full Device Assemblies

- Automated Molding Cells

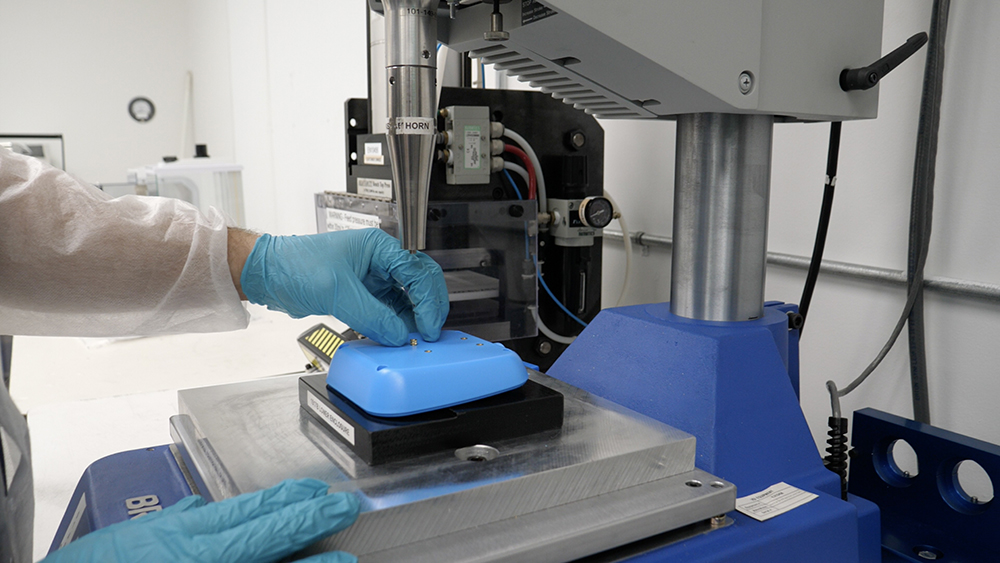

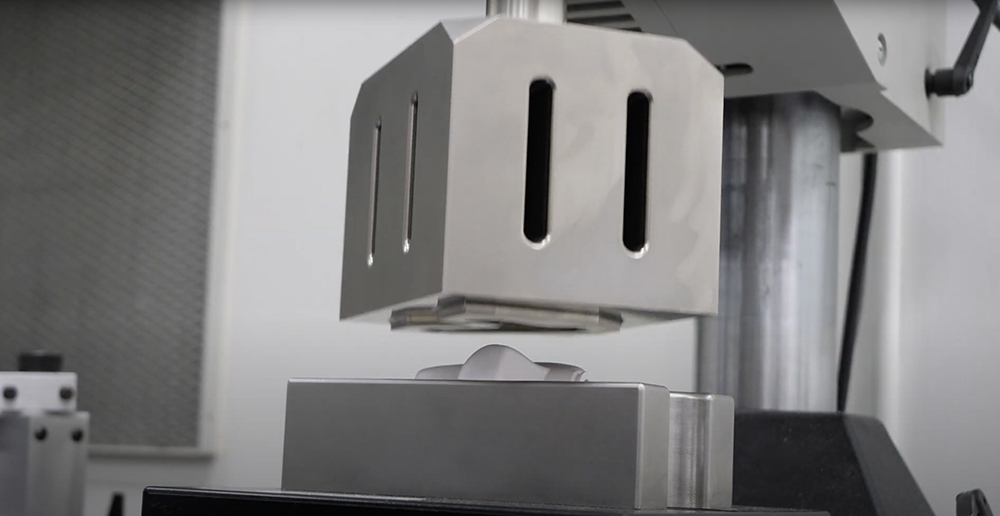

- Ultrasonic Welding & Degating

- Adhesive Bonding

- Pad Printing

- Custom Packaging & Heat Sealing

- Sterilization Management

- Barcoding & UPC Labeling

- IFU Cards (Instructions for Use)

- Laser Marking

- Leak Testing

Taurus Engineering is ISO 13485 certified, and FDA registered, specializing in medical device design, development, and manufacturing.

Learn more about our full-service contract manufacturing capabilities.