Clean Room & Non Clean Room Molding

Our Class 7 cleanroom meets strict ISO 13485 standards for medical products, ensuring high-quality process and tool validations. Equipped with HEPA filtration and positive airflow, we maintain the highest cleanliness and product quality standards.

Production Molding

Taurus Engineering embraces short-run production orders with flexibility and efficiency. We’ve developed processes to ensure fast setup, quality standards, and quick order turnaround, perfect for Just-In-Time (JIT) demands and low-inventory needs.

Unique Molding Capabilities

We specialize in challenging and complex molding with superior tooling, advanced equipment, and trained staff. Whether for low or high-volume runs, we meet customer schedules, offer competitive pricing, and maintain rigorous quality standards.

- Overmolding: Aluminum, steel, copper, tubing, and plastics

- Insert Molding: Cost-effective hand-loaded inserts

- Versatility: Molding of flexible and rigid resins

- Soft Touch Molding

- Cellular Manufacturing: Assembly, ultrasonic welding, pad printing, and packaging

- Short-Term Implantable Medical Devices

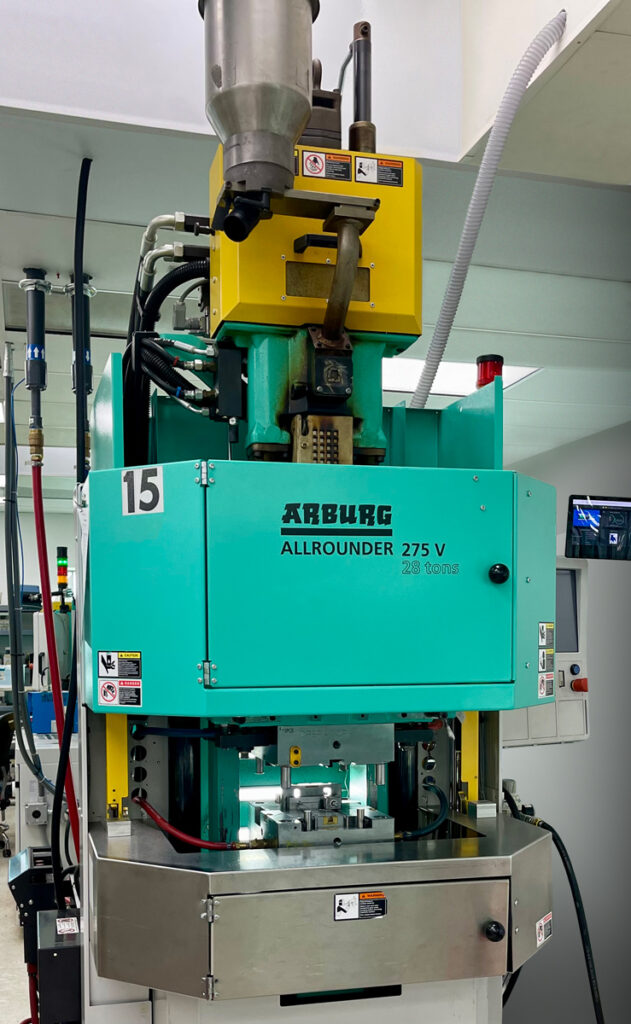

Diverse Range of Molding Equipment

We utilize a variety of advanced equipment to meet diverse molding needs:

- 20 injection molding presses, ranging from 28 to 300 tons

- Vertical presses for precise and efficient insert loading

- Shot capacity up to 28 ounces

- Arburg ALS software for optimal performance and process control