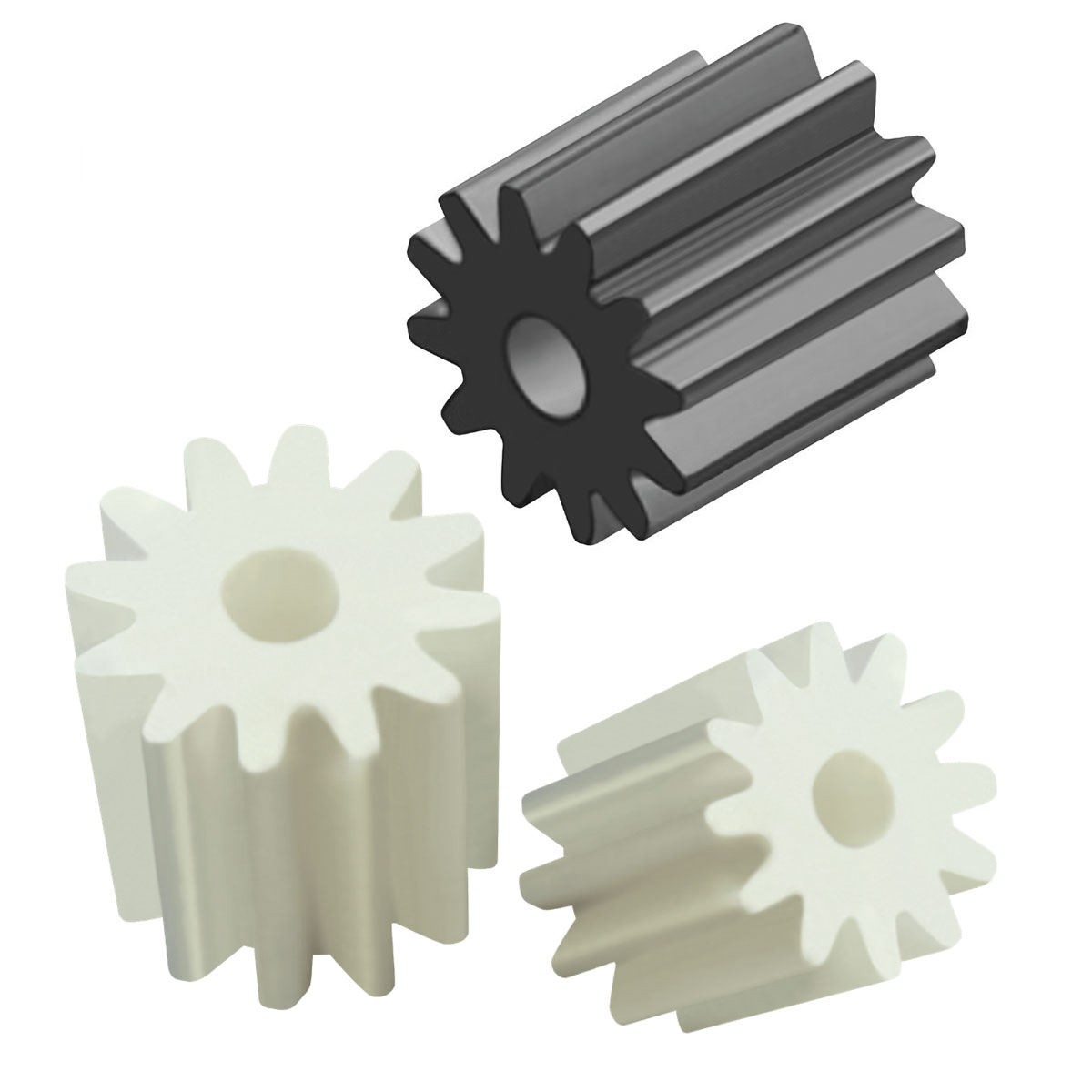

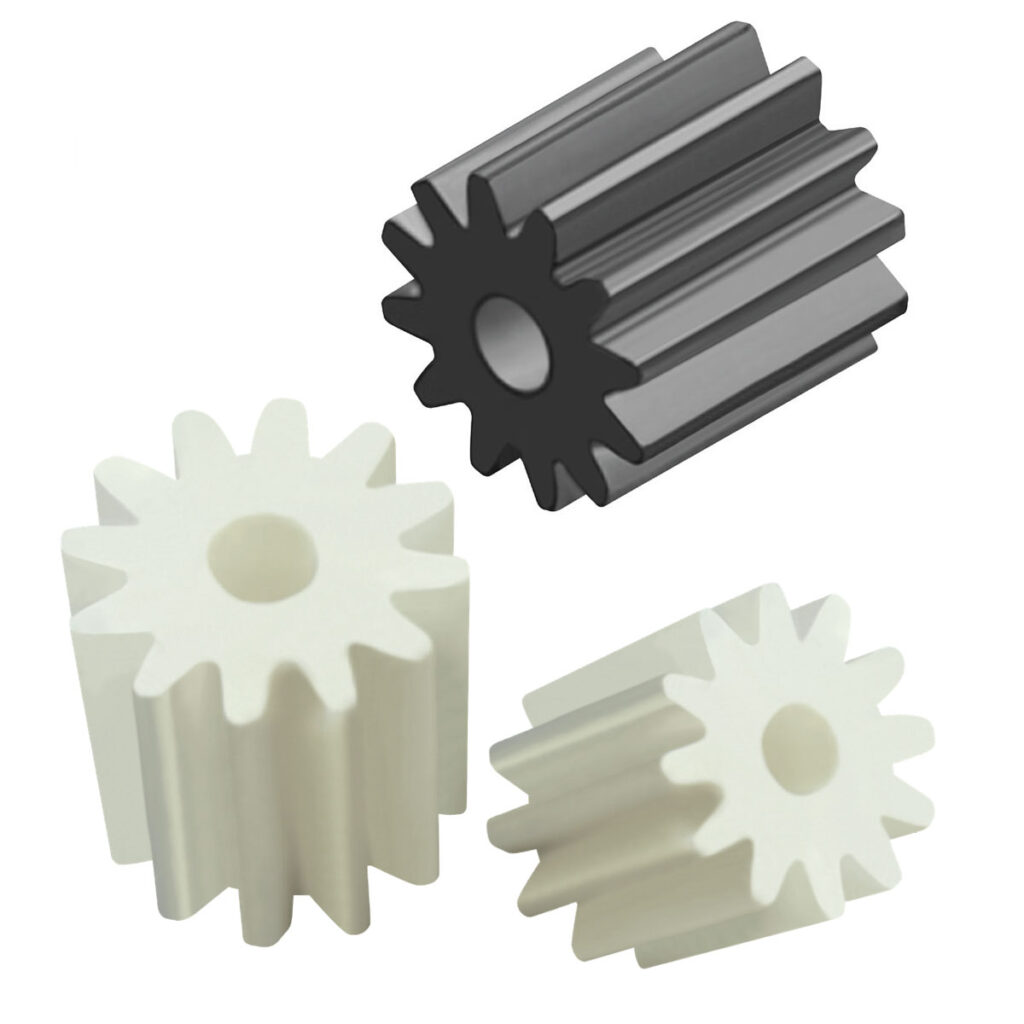

In summary, the production of Medical Gear using Delrin 500P NC010 with Quick Turn Development and a single cavity injection mold demonstrates a fast and efficient manufacturing process. Taurus delivered this critical component in 17 days with full First Article Inspection report indicating all dimensions within print specifications. The emphasis on DFM, precision, and quality control ensures that the final product meets the required specifications and regulatory standards for medical applications. The provision of ISO13485 certifications further reinforces the commitment to delivering a reliable and high-quality product to the market.

- Material Used: The Medical Gear was molded using Delrin 500P NC010. Delrin is an acetal resin known for its excellent mechanical properties, low friction, and dimensional stability. The choice of Delrin 500P NC010 is suitable for medical applications, due to its biocompatibility and resistance to chemicals and sterilization methods.

- DFM (Design for Manufacturability): A complete Design for Manufacturability (DFM) process was performed, indicating that the design of the Medical Gear was optimized for efficient and cost-effective production. DFM involves considering manufacturing constraints during the design phase, which leads to smoother production and higher quality products.

- Injection Mold: A single cavity class 102 injection mold was designed and built for manufacturing the Medical Gear. The use of a single cavity mold suggests that the production volume might be lower, but it allows for quicker turnaround times during the molding process.

- Hot Tip: The injection mold included a hot tip. Hot runners are a system used in injection molding to keep the material molten and flowing within the mold, which can improve cycle times and reduce waste.

- Tool Sampling and Approval: The injection mold was sampled and approved, indicating that the manufacturing process underwent thorough testing and initial validation before proceeding to full-scale production. This step helps ensure that the molded parts meet the required specifications.

- Precision and Quality Control: The initial inspection of the molded parts showed that all print dimensions were within 0.001″ of the nominal values. This level of precision demonstrates our commitment to maintaining tight tolerances and high-quality standards.

- ISO Certifications: Each shipment of the Medical Gear is accompanied by ISO13485 certifications. This indicates that the manufacturing process adheres to the quality management standards set by the International Organization for Standardization (ISO). The ISO13485 certifications provide assurance of consistent quality and adherence to industry best practices.