Design For Manufacturability (DFM)

Taurus Engineering is committed to mold/part design assistance and building quality precision tooling, within budget, on time, and per customer specifications. Understanding the importance of early involvement and close collaboration between customer and supplier, we work with design engineers to ensure streamlined and efficient product development, from concept to the marketplace.

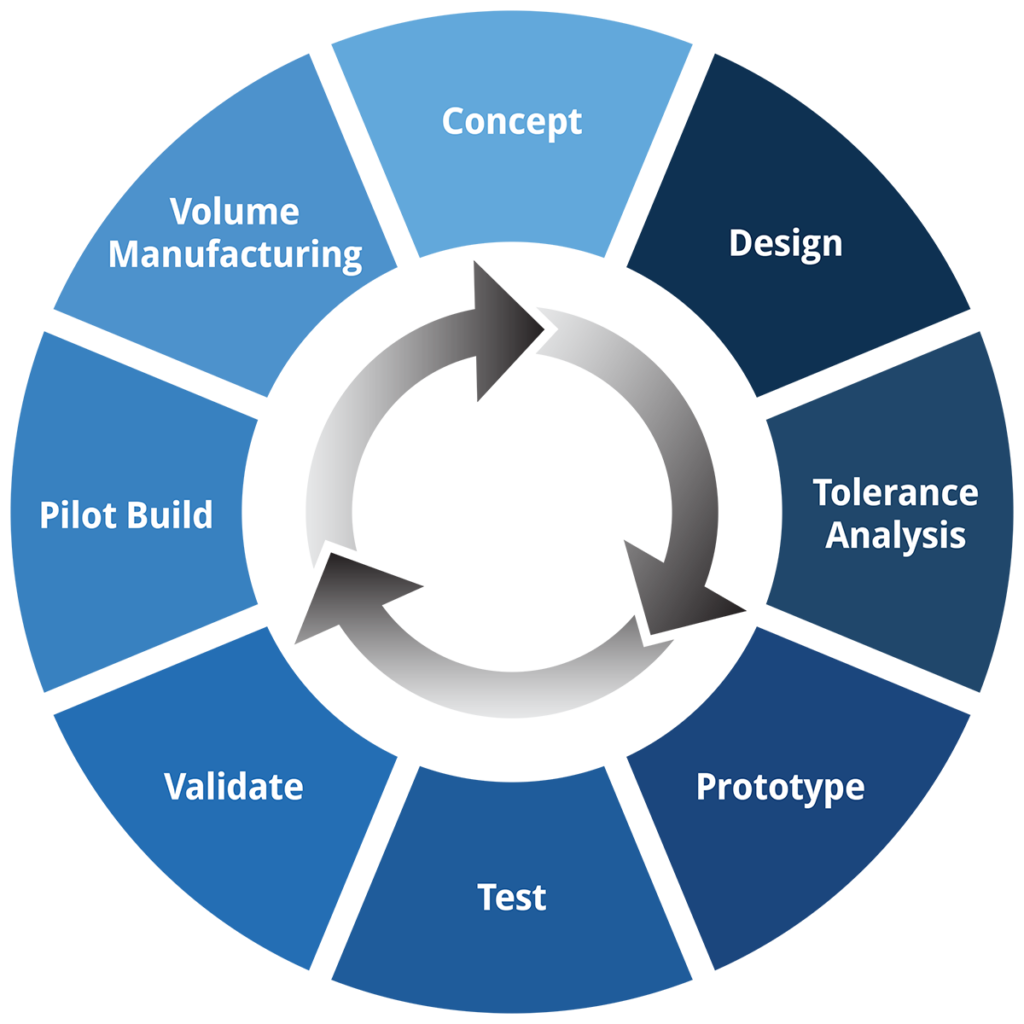

Product Development Cycle

Concept

Bring together key players for collaboration.

Design

Provide assistance to assure moldability.

Tolerance Analysis

Review of critical dimensions for cost

effective parts.

Prototype

Execute functional components using bridge tooling.

Test

Prototype review and functional testing.

Validate

Qualifying a mold and validating the molding process.

Pilot Build

Manufacturing low-volume for initial needs.

Volume manufacturing

Scale approved components,

assemblies and products to required volume.

Taurus Engineering can provide a complete comprehensive design report with each part.

An in depth DFM report is the first step to success!

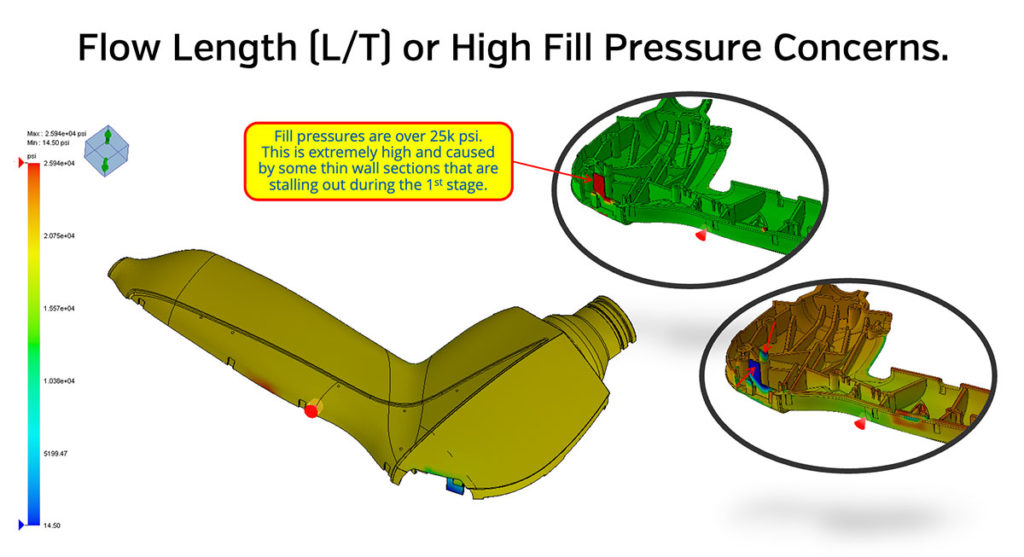

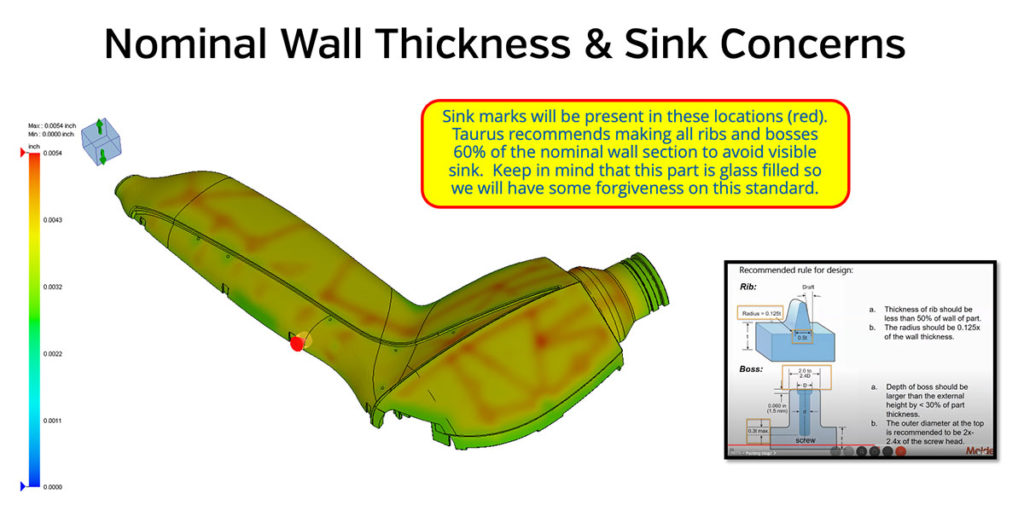

Some of the risks that risk that would be detected during the DFM process:

- Resin to be used – shrinkage

- Parting line / draft analysis

- Fill analysis

- Thickness design – rib thickness, uneven wall sections, thin wall

- Gating defined. Locations / Numbers / Sizes

- Weld Lines

- Finish or polished surfaces

- Engraving